Important details Concerning Commercial and Industrial Drying Ovens

Introduction

Drying ovens used in industry are components of high-tech equipment that are specifically intended to remove moisture. These pieces of apparatus are put to extensive use in both commercial and academic institutions..The functioning and application of these ovens, in addition to their designs, will determine the degree to which they are complicated.

Research and careful planning are required in order to locate the industrial ovens that are most suited to meet your requirements. However, if you are aware of what to look for, you will be able to make sure that the equipment you buy is appropriate. You are able to make improvements to your production processes if you have a high-quality oven and the appropriate application. The ability to manufacture a safe product in a consistent and reliable manner is essential to the success of any organization, regardless of the many obstacles faced by the sector.

These industrial heaters are in great demand on the market because of the ease with which they can be operated, the excellent performance they provide, the little maintenance they need, the energy – efficient they offer, the longevity of their design, and so on. The offered Drying oven from Drying oven manufacturers India are capable of being customized in accordance with the clients’ bordered requirements and preferences.

Utilizing an industrial oven is dependent on the following four key considerations:

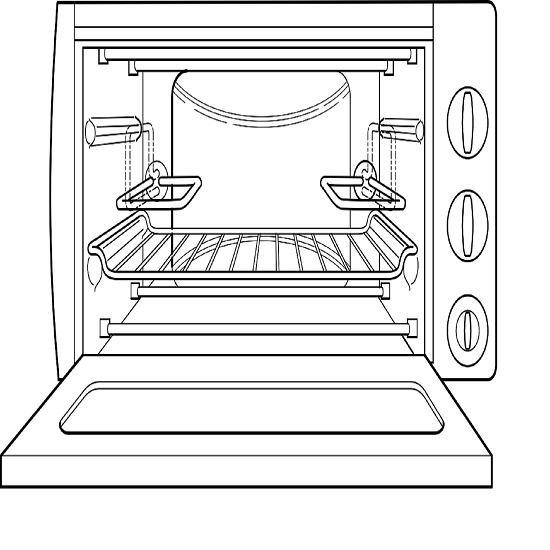

- When you are ready to start utilizing your oven, it is vital to have the appropriate product load. This may be accomplished by loading your batch. In order to get the temperature of the product up to the appropriate level, you need to take into account the amount of heat that your load demands, as well as losses from the exhaust system and the wall, and you also need to bring the oven up to the ideal temperature before loading it.

- Preheating the oven: If you have the appropriate tools, you can make certain that your items achieve the specified temperatures and continue to maintain those temperatures throughout the whole process. You have two options to choose from in order to get at the desired set-point. Either you can load your batch, set the desired temperature with a set-point controller, and run the oven until it reaches it, or you can use a ramp or soak programmer, which enables you to create several set points as well as plateaus. Either way, the oven will run until it reaches the temperature you want it to be at.

- Temperature regulation: As the oven warms your product, you are responsible for ensuring that the temperature is maintained in an appropriate manner. The use of soak durations is a good strategy since it involves measuring the temperature difference between the object being soaked and the oven area that it is being soaked in using a thermocouple.

- The last step in the procedure is turning off the heat in the oven so that it may cool down. You will need to devise a method for effectively exhausting the hot air while simultaneously allowing air at normal temperature to enter the oven and move around the space. This procedure may be carried out manually, or it can be controlled using a programmer instead.

Features of Drying oven

- The size of the oven may be modified to accommodate the product and the procedure.

- Extraordinary levels of cleanliness for delicate goods

- Resistance to thermal shock for processes that move quickly

- Best optical characteristics

- Outstanding mechanistic stability, even when subjected to very high temperatures

- Exceptionally high level of processability with adaptable oven size

- Very high degree of temperature field uniformity due to the presence of diffuse reflection

What are Infrared dry oven?

Infrared dry oven is used to heat anything if the surface you’re trying to warm up is flat. As a result of the fact that infrared ovens function according to the concept of radiation, the area that is heated is restricted to the region where the infrared rays are concentrated. One of the benefits of using an infrared oven is that it can reach the needed temperature for heating the components in a shorter amount of time. Additionally, in the occurrence that just the component’s outer surface has to be heated, the rays will concentrate their energy on the component’s surface, which will reduce the amount of heat that is lost as a result of heat transfer occurring inside the component. The size of the oven in industry may be modified to accommodate the product and the procedure.